How to Reduce Unplanned Downtime (Guest Blog)

Two words that nobody in manufacturing wants to hear are unplanned downtime. For the financial team, unplanned downtime means substantial or even catastrophic operating losses. For the operations team, unplanned downtime means disrupted schedules, intense pressure, heightened potential for accidents, and potentially a cascading effect of additional production stoppages. For sales teams, unplanned downtime means disruptions in service, possible quality issues, extended lead times, and jeopardized or lost customers.

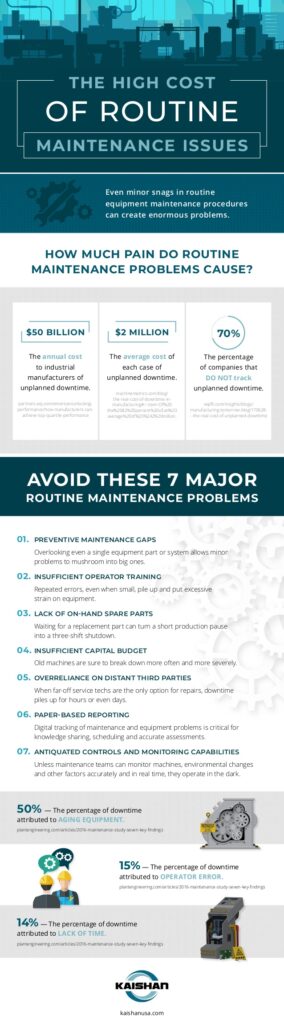

The infographic below, The High Cost of Routine Maintenance Issues, makes two very important points. First, the cost of unplanned downtime is enormous — this is the bad news. Second, many cases of unplanned downtime can be minimized or eliminated — this, of course, is the good news.

The infographic describes at a high level how proper management of routine maintenance processes prevents small equipment issues from becoming big ones. It’s important reading for anyone involved with the production side of a manufacturing business, or a distribution business that is highly automated. By implementing the proper preventive maintenance procedures and attending to other aspects of the operation with an impact on equipment performance, operations are almost certain to maximize uptime and keep all internal departments and all the company’s customers happy.

Most of unplanned downtime causes described in the infographic can be traced back to running things too tightly. There is a fine line between a lean operation and one running too lean. Reducing inventory costs is admirable but doing it by failing to stock critical spare parts can create downtime situations that easily wipe out the savings produced by the inventory reductions. Along similar lines, pushing for higher and higher throughput is admirable, but when doing so puts excessive strain on aging equipment, the company is almost asking for an unplanned downtime crisis. And again, striving for maximum productivity is admirable, but when the staff is too busy to maintain a thorough preventive maintenance schedule, a single loose thread could cause an entire machine to unravel.

Technology also plays an important role in preventing unplanned downtime. A surprising number of manufacturers press on with written documentation and reporting in the maintenance department, making transparency difficult and creating an environment where the maintenance crew is continually reacting to problems instead of having the data it needs to prevent them in the first place. As digital platforms grow ever more robust and IoT technology becomes more sophisticated, manufacturers will have powerful tools at their disposal to make massive gains in downtime prevention.

Our guest blog is from Kaishan USA (One of the world’s largest manufacturers of compressed air equipment) and Straightnorth (Digital Marketing agency). Kaishan Shop provides a certified start up from one of their factory-trained distributors with every Kaishan unit purchase.